Pricing

Plastic Food Packaging Pricing, Simplified

Keeping it simple means removing complexity, making it easier to understand key pricing drivers like resin, design, and supplier partnerships. Use these insights to make smarter choices, stay on budget, and unlock greater value for your business.

The Truth Behind The Price

At Inline Plastics, we believe in honesty and education. Our goal is to provide transparent answers so you can be confident in your packaging decisions. One of the toughest questions is: “How much does this product cost?”

The truth is, packaging prices aren’t simple. Costs vary by many factors and as a manufacturer that sells in truckload quantities, the final prices are also influenced by logistics and distribution which we do not control.

On this page, we’ll break down how food packaging pricing works, share cost ranges for common sizes we see in the market, show where Inline Plastics fits in the market, and even give you an estimator for a ballpark price range (yes, despite a lot of vagueness), so you’re informed and ready for a sales conversation.

What Impacts Container Pricing?

Plastic packaging pricing is shaped by several factors.

Raw Materials

The type of plastic (resin) you choose and market fluctuations in raw materials can drive prices up or down.

Sheet Manufacturing

Converting resin into plastic sheet involves energy and processing costs, which vary by material and thickness.

Package Design

Complex shapes, thicker materials, and features like compartments require more tooling investment and material, impacting cost.

Package Manufacturing

Beyond machines themselves, the forming, trimming, and assembly processes add labor and operational expenses to the final cost.

Production Volume

Higher volumes reduce per-unit cost by spreading tooling and setup costs across more units.

Logistics

Shipping costs depend on factors like full vs. partial truckloads, which influence your final price.

Let's Clear This Up:

Price vs. Value: Know the Difference

When it comes to packaging, rock-bottom pricing can come with hidden trade-offs.

Ultra-low prices often mean:

- Inferior materials and performance

- Minimal service and support

- Unstable or inconsistent supply chains

Higher-value partners invest in:

- Trusted products that meet industry standards

- Reliable expertise you can count on

- Reliable delivery and long-term stability

Why Leading Brands Trust Inline Plastics

Discover how high-quality, reliable food packaging can streamline your operations, enhance product presentation, and ensure safety.

Innovation

Market-transforming products make food shine and your brand lead.

Quality

Reliable quality and crystal clarity make your food the hero — from production to consumer.

Service

You can count on packaging that arrives on time — and if something changes, you are the first to know.

Trust

Trusted by customers who expect reliability, quality, and peace of mind.

Packaging Automation

A dedicated in-house team will help you grow your output while limiting your labor costs!

Thermoformed in the USA

SQF-certified food packaging you can trust for faster delivery and strict safety compliance.

The Value Behind the Price

Understanding Inline's Premium Pricing

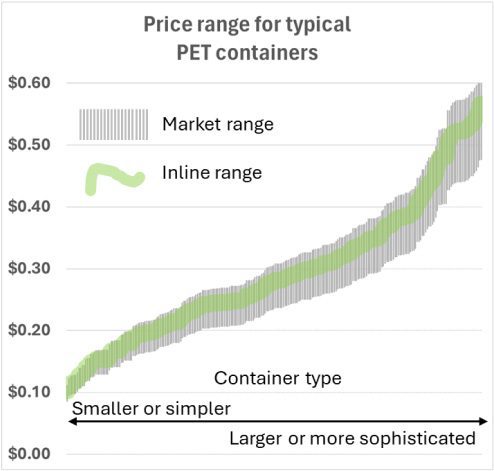

With so many factors influencing packaging costs, pricing can vary widely, even for similar-looking items. Most common containers fall within the $0.15 to $0.75 range (with some large size outliers that are priced significantly higher and not reflected in this chart), with some variation based on size, material, and design. While it’s possible to find options across a 20-30% price spread, the difference in cost often reflects meaningful differences in value. Inline products are generally priced at a premium compared to lower-cost alternatives — not just for better aesthetics, but for what they consistently deliver:

- Reliable performance

- On-time delivery

- Dependable supply

That small price difference pays off in fewer disruptions, stronger brand presentation, and better customer loyalty. In the long run, it’s an investment that supports smoother operations and higher sales growth.

This chart is to provide a general overview of typical common container pricing. It is not intended for use as a formal quote or for detailed pricing analysis. Final costs are influenced by several variables, including order volume, customization, materials, and logistics that are not fully captured in this simplified representation.

Price Calculator

Explore the Price Range of Your Desired Package

Use this price calculator to explore the price range for the product you have in mind. And remember, your advisor is ready to connect, answer questions, and tailor both the packaging and pricing to fit your business needs.

Plastic Packaging Pricing FAQs

Below is the list of most common questions our team gets when it comes to pricing:

How much does plastic packaging cost?

That’s a great question, and the truth is, pricing isn’t one-size-fits-all.

Think of it like building a custom suit: the material, the design, the quantity, and even how quickly you need it all play a role. Factors like resin type, mold complexity, order volume, and supply chain pressures can affect the final cost.

But here’s the good news — you don’t have to figure it out alone. We guide customers through a transparent pricing process, so they can make confident decisions that align with their product goals and packaging needs.

We’re here to help you get clarity, not surprises. Let’s talk about your priorities and build from there.

In the meantime, check out this article in our Learning Center: Inside Plastic Food Packaging Pricing: Factors That Matter

Can I buy plastic packaging from you directly?

You can, but it depends on what you’re looking for and where your business fits.

Buying direct makes sense when you’re ready for things like custom design, large-scale ordering, or strategic partnerships. It gives you more control, transparency, and often better long-term value.

But it’s not always the best route for smaller volumes or when speed is your top priority — that’s where distributors might shine.

Our goal? Helping you choose the path that works best for your business — not just ours. Let’s talk through your needs and find the right fit.

Check out this article for a more detailed explanation in our Learning Center (don’t be swayed by the title): Why Can’t I Buy Plastic Food Packaging Direct?

Can you beat the price of my current package?

If you’re focused on driving consistent growth, reducing supply headaches, and strengthening your brand, you know that the lowest price doesn’t always lead to the best outcome.

Many of our customers came to us after realizing that small cost savings with their previous supplier led to bigger disruptions, missed deliveries, inconsistent quality, or supply chain instability.

When you choose Inline, you’re choosing:

- Packaging that performs reliably on your lines.

- A dependable, domestic supply chain.

- On-time delivery that supports your operations—not disrupts them.

We won’t always be the lowest bidder, especially compared to overseas suppliers who may skip important investments in compliance, quality, and people. But we will always be a strategic partner focused on your long-term success, not just a short-term transaction.

We’re happy to explore pricing with you based on your volume, goals, and production needs because your packaging shouldn’t just fit your budget. It should help your business thrive.

If you’re interested in learning about domestic vs. foreign manufacturing, take a look at this article in our Learning Center: Is American Plastic Food Packaging Actually More Expensive?

Ready to Take Control?

Join the 2000+ Brands Thriving With Us

What to expect after you submit this form

Confirmation: You’ll receive a confirmation email within 2 hours letting you know we’ve received your request.

Expert Guidance: A dedicated advisor will connect with you within 1 business day to have a meaningful conversation about your request.

Clarity & Confidence: Together, we’ll determine if Inline Plastics is the right fit for you.