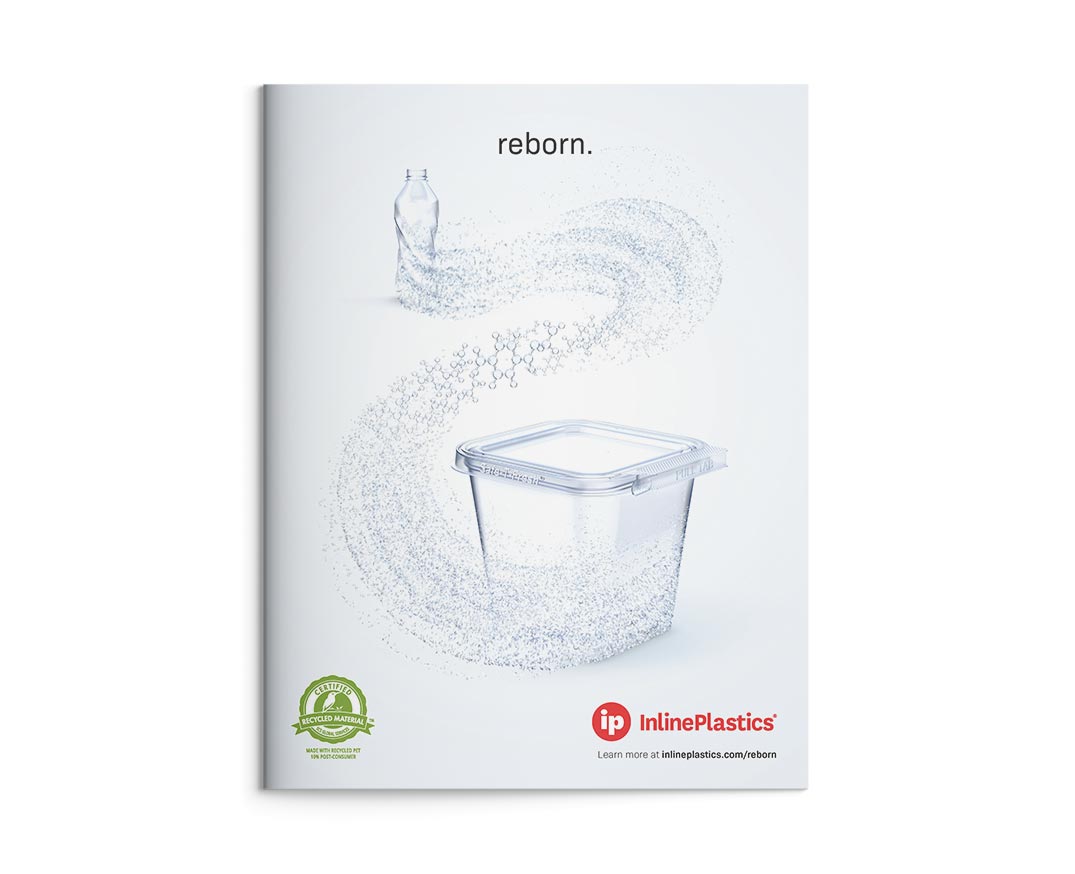

reborn.

PET is reborn at Inline Plastics

Packaging For a Better Planet

Inline Plastics is the first thermoformed food packaging manufacturer to use post-consumer content made with cutting edge technology, called Advance Recycling. We call this PET, rDPET (recycled Direct to Sheet PET).

Through our reborn process, all our PET products are made with 10% post-consumer recycled PET.

We believe that integrity and transparency are an important part of doing business and this is why we have an independent third-party, SCS Global Services, to verify our post-consumer recycled material claim. By showing data behind our claim, we build trust with our customers.

Advanced Recycling

The advanced recycling process breaks down post-consumer flake into its molecular building blocks: PTA & MEG molecules

rDPETTM

These post-consumer molecules are then polymerized with virgin ones using an environmentally friendly ‘direct-to-sheet’ process

Through this proprietary process

plastic can be turned into clean, new plastic again and again, preserving quality, so it doesn’t have to end up in a landfill

Our thermoforming production is powered in part by solar panels

Our Commitment

By using rDPETTM vs PET, Inline Plastics…

Diverts over

1 Billion

water bottles

from the ocean and landfills annually

Generates over

50% energy savings when producing rDPET™

Decreases carbon footprint equivalent to 112,000 acres of forest per year

Saves greenhouse emissions equal to 233 million miles driven