-

Poor de-nesting design causes chaos: Stuck containers lead to spills, wasted product, and workers cleaning instead of checking quality.

-

De-nest lugs fix the issue: Smart lug patterns (A-B-C) prevent containers from locking but need upkeep.

-

Teamwork matters: Manufacturers design solutions; processors maintain and communicate to keep lines running.

-

The payoff: Smooth automation, less waste, steady schedules, and higher efficiency.

Food processing professionals know that automation lines are only as strong as their weakest link. Many people overlook how a simple action, like separating “nested” containers (packages that are stuck together), can halt an entire production line. When food starts flying off the conveyor belt and workers are slipping on cupcakes and banana peels like a Three Stooges skit, the frantic rush to clean the machines, belts, and floor makes one thing clear: there’s a problem. This chaos shows the negative impact of poor de-nesting design. It’s the industrial equivalent of a house of cards: everything looks stable until one small piece refuses to cooperate.

For years, Inline Plastics has provided automation solutions to food processing facilities. We have seen how effective container design can impact production efficiency and would like to share our insights with you.

It turns out that containers can be surprisingly clingy — and not in a good way. Recent observations from numerous processing plants demonstrate the widespread prevalence of this issue. They highlight significant gaps in the food industry’s approach to packaging automation.

This article looks at the challenges of de-nesting containers. It will illustrate how poor separation can cause problems. Additionally, it will explain why packaging manufacturers and food processors must collaborate to address this issue. After all, we’re in this together!

When Containers Refuse to Let Go

Every food processing pro has seen nesting. Understanding the mechanics of nesting shows that this is more than an inconvenience. It’s an engineering challenge with serious operational effects.

When de-nesting fails on an automated line, issues spread fast in a food processing operation (prepare yourself — this is going to get ugly). The automation system typically picks one container at a time. However, it suddenly handles two containers that are stuck together. These doubled containers are too low for filling. As a result, baked goods and prepared salads can miss their targets and spill everywhere on the line. In plain English, the automated line can quickly become a “nightmare pile” of containers and wasted food.

Workers who are supposed to monitor quality and conduct spot checks often end up as cleanup crews. They remove waste products and attempt to repair jammed equipment. Cupcakes, pasta salads, nuts, and candy all share a common issue: automation lines that were once self-sufficient now require regular human oversight.

The economic impact extends far beyond wasted products. The containers that have gone through the automation line cannot be reused and are considered an economic loss. Production schedules fall behind, labor costs rise, and the efficiency gains that made automation worthwhile vanish across the industry. But don’t panic. There’s hope.

How Do We Prevent De-Nesting Failures?

The engineering solution includes “de-nest lugs.” These are small, designed divots with undercut shapes. They stop containers from sitting flush against one another. These features act like small spacers. They create natural separation points that automation equipment can use. However, the devil lies in the details of their implementation. Let’s examine this further.

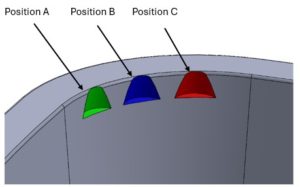

Possible de-nest lug placements (not all three would be present on the same package):

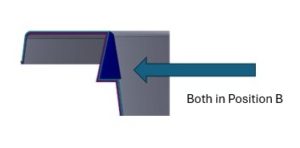

Nested packages — when two lugs align in the same position and lock together:

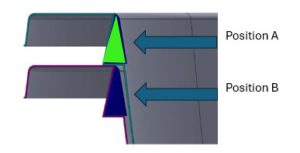

Alternating de-nest lugs stacked — lugs properly placed in different areas:

Production Complexity and Human Error

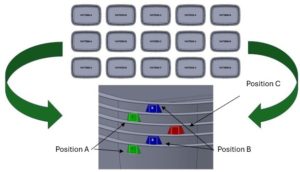

Here’s where the story gets complicated. Modern thermoforming tools shape plastic with heat. They can produce many containers at once, arranged in complex patterns. Manufacturers need to create different lug patterns to avoid nesting. We’ll call these patterns A, B, and C. This way, containers in the same row won’t have the same pattern. One row might run A-B-C-A-B, guaranteeing that stacked containers can’t perfectly nest. By alternating the placement of each of these lugs in a row, the containers are more easily separated when de-nesting.

One example might be a 15-up (meaning capable of producing 15 packages in one go) tool with a 3×5 layout and an alternating de-nest lug pattern:

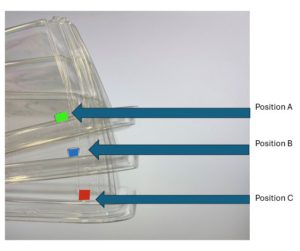

Stacked containers (on a tilt for demonstration) with alternating de-nest lugs (A, B, and C positions):

Are you still with us? Good! You’re doing great!

Good manufacturers ensure that the system stays in proper working order and that they remain aware of its requirements.

This approach requires more careful tracking. Manufacturers need to know which mold parts are assigned to which locations, and they must also ensure proper installation. The system performs well when cared for correctly, but it demands more attention than simpler designs.

Ongoing upkeep becomes essential with these pattern systems. Regularly checking equipment and following proper procedures keeps everything running smoothly. When facilities invest in strong service programs and train their operators effectively, the patterning approach works reliably in various production settings.

Engineering Solutions and Best Practices

Solving de-nesting problems requires teamwork between packaging manufacturers and food processors. Packaging suppliers should find a balance between strong de-nesting features and manageable production. At the same time, food processors must practice proper handling and maintenance.

The best de-nesting lugs create grooves or divots that prevent nesting while still being easy to manufacture in various patterns. Smart designs utilize geometric patterns, such as puzzle pieces that fit together predictably and seamlessly. The goal is to create enough space to break the suction effect without making containers wobbly or hard to handle.

For food processors, success means having well-designed containers. They’re more than just basic plastic boxes. When nesting problems arise, contact your packaging suppliers immediately. This way, you can find specific solutions instead of generic fixes.

Your First Steps: Preventive Maintenance and Collaboration

Prevention begins with knowing that containers can nest if you squeeze them hard enough (let’s not try to become The Incredible Hulk here). We’re not saying the containers will stay intact. The goal isn’t making containers that never stick — it’s ensuring that you have packaging designed by a manufacturer that separates easily during everyday use. Regular maintenance of equipment (such as de-nesting systems) is necessary. Clear communication between packaging suppliers and processors is also important.

Smooth Operations and Reduced Waste

When de-nesting systems work well, they seem invisible. Containers separate easily, products fill correctly, and automation lines run smoothly at full capacity. Workers focus on quality monitoring and value-added tasks rather than cleaning up messes. Production schedules stay predictable. The efficiency gains that made automation worth the investment are now happening.

Facilities that have mastered de-nesting see big gains in equipment effectiveness. They also reduce waste in all product categories. Their success proves that good engineering works and shows others how to solve similar problems. When companies view de-nesting as a key component of their system, they increase their chances of long-term success in the competitive food processing industry.

Stick to the Plan (But Not Each Other)

De-nesting may seem minor in food processing automation, but it’s crucial. It impacts everything that follows. Food processing experts who partner with manufacturers on proper design already understand this.

In an industry where every penny counts and efficiency rules, getting the basics right isn’t just innovative business — it’s survival.

After all, nobody wants their automation line to have commitment issues, especially when those containers refuse to let go at all the wrong moments.

Are you interested in learning more about automation solutions for your business? Check out our ROI calculator today and see if automation is right for you!