Sep 22, 2025

Stuck Together: The Hidden Cost of De-Nesting Failures

At a Glance Poor de-nesting design causes chaos: Stuck containers lead to spills, wasted product, and workers cleaning instead of checking quality. De-nest lugs fix the issue: Smart lug patterns (A-B-C) prevent containers from locking but need upkeep. Teamwork matters: Manufacturers design solutions; processors maintain and communicate to keep lines running. The payoff: Smooth automation, […]

Read More +

Sep 17, 2025

Purchasing Directly from a Manufacturer vs. Through Distribution

At a Glance Direct purchasing from a manufacturer and buying through distribution models each have unique strengths — direct buying offers lower per-unit costs for large, consistent orders, while distributors provide flexibility, storage space, smaller order quantities, “just-in-time” delivery, safety stock, and broader product variety. Total cost matters more than unit price; storage, labor, and […]

Read More +

Sep 15, 2025

Are Recyclables Declining in Value? What Food Business Professionals Need to Know

At a Glance Recyclables declining in value is real. Cardboard, plastics, and metals are worth far less than a year ago. Multiple factors drive the drop. Lower demand, oversupply, and high energy costs all play a role. Food businesses feel the squeeze. Lower value from cardboard and plastics means higher waste costs. Smart operators adapt. […]

Read More +

Sep 10, 2025

What Packaging Material Can Go from Freezer to Oven Without Breaking?

At a Glance CPET packaging handles -40°F to 420°F and is perfect for freezer-to-oven meals. Made with special thermoforming tools and processing, it keeps its shape and blocks oxygen, water, and grease. Recycling is a challenge, but new CPET Light and TPET offer clearer, greener options. Use CPET for extreme temps; choose alternatives for moderate […]

Read More +

Sep 08, 2025

Is All Plastic Food-Safe? What You Need to Know

At a Glance Resin identification codes (the triangles made of chasing arrows) show the plastic type, not whether it’s certified for food contact; even common codes like PET (1) or PP (5) can be unsafe if made from non-compliant materials. Food-safe plastic isn’t guaranteed by appearance or resin codes — true safety requires FDA-approved materials, […]

Read More +

Sep 03, 2025

Why is PET the Top Packaging Material for Cold & Ambient Fresh Food?

At a Glance PET Packaging Boosts Visibility: Crystal-clear PET packaging enhances product appeal, improves sales, and simplifies inventory management, lowering handling costs. Extends Shelf Life: PET’s strong oxygen barrier keeps products fresh longer than packaging with lower barrier properties such as paper or polystyrene, reducing waste compared to other materials. Sustainable & Adaptable: PET has […]

Read More +

Aug 27, 2025

Learn What Separates Elite Packaging Manufacturers from the Rest

At a Glance Choosing the right packaging manufacturer is critical — late shipments, poor quality, and weak service can damage profits and reputation beyond repair. A great partner practices manufacturing vigilance: consistent quality checks, strong efficiency metrics, and systems that prevent mistakes before they happen. Top manufacturers innovate with new materials, automation, and sustainability efforts, […]

Read More +

Aug 25, 2025

An Introduction to Packaging Claims for Food Industry Professionals

At a Glance Packaging claims must be truthful, substantiated, and match how the audience interprets them. FTC and states can penalize false or misleading claims, especially on hot topics. Environmental claims need strong proof to avoid greenwashing. Verify supplier claims, consider context, and choose partners who back up promises. Walk down any grocery aisle, and […]

Read More +

Aug 20, 2025

How Your Food Packaging Survives the Commercial Freezer Challenge

At a Glance Packaging in freezers must survive rapid drops to -40°F without cracking or losing clarity. APET with impact modifiers resists cold and stays clear; polypropylene needs additives but can lose transparency. Each manufacturing heat cycle weakens material, making it more brittle in extreme cold. Success means balancing cold resistance, clarity, barrier strength, and […]

Read More +

Aug 18, 2025

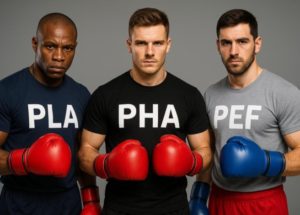

PET and The Battle of Bioplastics Part III: PEF

At a Glance PEF and PET packaging: PEF is a plant-based rival to PET with better performance. Why it matters: PEF fits existing PET lines — no overhaul needed. Top benefits: Better barriers, more heat resistance, stronger, greener. Big hurdles: High cost, low supply, no recycling system (yet). You’ve seen this story before — another […]

Read More +