At a Glance

- Resin identification codes (the triangles made of chasing arrows) show the plastic type, not whether it’s certified for food contact; even common codes like PET (1) or PP (5) can be unsafe if made from non-compliant materials.

- Food-safe plastic isn’t guaranteed by appearance or resin codes — true safety requires FDA-approved materials, proper migration testing, and verified compliance documentation.

- Strong supplier vetting includes food-contact letters, food-safety certifications, migration testing results, MSDS checks, and annual documentation updates.

- Red flags include vague safety claims, missing documentation, offshore suppliers without proper FDA records, and prices far below market rates.

Your customers trust you with their health every time they buy your product. They believe the shiny container holding their fresh salad or the strong tray with their meal is as safe as the food inside. But here’s the uncomfortable truth that keeps quality managers awake at night: not all plastics are safe for food contact, and the wrong choice could turn your brand into tomorrow’s recall headline.

Believing that “plastic is plastic” has led to expensive recalls and damage to brands. This problem arises when non-food-grade materials are used in food packaging.

As you perfect recipes and grow your market share, watch out for a hidden danger in your supply chain. Some packaging materials may look professional but lack the necessary safety credentials for food contact.

With 50+ years in fresh food packaging, Inline Plastics has built solid expertise in food-safe plastic manufacturing. This experience gives us valuable insights into food-contact materials and how to evaluate suppliers properly.

This article explains how to spot food-safe plastics versus harmful ones. It covers the documentation needed to protect your brand and highlights red flags to watch out for with some suppliers.

The Costly Assumption That All Plastic Is Food-Safe

Every day, food companies make packaging decisions based on price, appearance, and functionality. Many don’t see they’re betting on food safety. The stakes include product recalls, regulatory fines, and lasting damage to consumer trust.

Every day, food companies make packaging decisions based on price, appearance, and functionality. Many don’t see they’re betting on food safety. The stakes include product recalls, regulatory fines, and lasting damage to consumer trust.

Not all plastics meet the stringent requirements for food-contact materials. That container may seem like food-grade packaging. However, it could have chemicals that leach into food. It may not have proper migration testing or be made from non-approved resins. The FDA has strict food safety standards for packaging. However, not all packaging is made in America. Different nations may have different standards.

When these materials fail, your brand takes the hit — not the packaging supplier who cut corners on safety testing.

The gap between “looks food-safe” and “actually is food-safe” has caught companies off guard. Import regulations differ a lot. Some manufacturers don’t grasp the difference between general-purpose plastic and food-contact materials. This distinction is as important as knowing candy from medicine.

Understanding the FDA’s Food-Contact Framework

Plastic food safety starts with Title 21 of the Code of Federal Regulations – specifically Part 177. This isn’t a suggestion box; it’s federal law that defines what can touch your food and what can’t.

The FDA keeps detailed lists of approved materials for food contact. For common plastics like PET (polyethylene terephthalate), PP (polypropylene), and HDPE (high-density polyethylene), the rules specify exact chemical recipes down to the last ingredient. Think of it like baking — you can’t just substitute flour for sugar and expect good results.

Migration testing is where the rubber meets the road. Suppliers must prove their plastics are safe for food. They need to test for chemical migration using water, alcohol, heptane, and other solutions under various conditions. It’s like a stress test for plastic behavior.

The rules also set temperature limits and food restrictions. A container that works fine for a cold salad might turn problematic with hot soup. There’s solid science behind those limits, rooted in experiences no one wants to repeat.

Decoding Resin Identification Codes

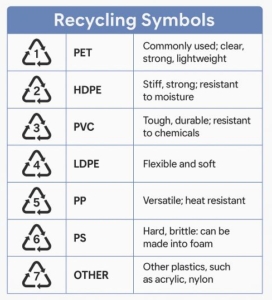

The numbered triangles on plastic containers are resin identification codes (RICs). They show the type of plastic, but they don’t ensure food safety.

Code 1 (PET) appears on most clear containers, soda, and water bottles. When properly made, PET offers excellent food safety.

Code 2 (HDPE) covers milk jugs and storage containers. HDPE provides good chemical resistance, meaning it doesn’t easily react with or break down when it comes into contact with acids, bases, alcohols, or detergents.

Code 3 (PVC) raises red flags for food contact. Some PVC formulations can meet FDA standards, but PVC isn’t usually the best choice. This is mainly due to worries about additives like phthalates. Some older-style packaging films and certain condiment squeeze bottles utilized PVC previously, but it’s very uncommon today.

Code 5 (PP) stands out in microwaveable containers and yogurt cups. It has excellent temperature resistance and ensures food safety when produced properly.

Code 6 (PS – polystyrene) has significant limitations. Much of it breaks down under heat and releases harmful compounds. Those warnings about not microwaving foam containers exist for solid scientific reasons.

Code 7 (Other) includes acrylics, nylons, and bioplastics such as PLA and PHA which can be food-safe. However, these materials aren’t recyclable with standard systems at this time. These materials can resemble PET, which may contaminate recycling streams. This is a frustrating setback for sustainability efforts. In plain English, they end up in landfills or are burned despite being created with good environmental intentions (a total bummer).

Key insight: Resin codes indicate the plastic type. They do not show whether it meets food-contact requirements. A Code 1 container made from non-food-grade PET poses the same risks as any other non-compliant material.

Embossing That Signals Your Plastic Packaging Is Food-Safe

One common source of confusion is symbols on packaging — aside from the resin identification codes. For example, the fork-and-knife embossing you sometimes see molded into containers is not a resin code but a food-contact symbol. It signals that the packaging meets food-safety standards for direct contact with food. While not required in the U.S., it’s widely used in Europe and export markets as a quick way to confirm compliance.

Your Documentation Defense Strategy

Smart procurement requires systematic verification of supplier claims. Hoping your packaging supplier follows food-safety rules isn’t a strategy — it’s a liability waiting to happen, so it’s important to stay vigilant.

Request food-contact letters immediately. These documents, known as letters of guarantee, confirm that materials follow FDA rules, such as 21 CFR 177.1630 for PET. Legitimate suppliers offer these without delay. If there’s any pause, it could mean compliance issues. In that case, you should run the other way.

Verify SQF certification status. Ask suppliers if they have a food-safety certification such as SQF (Safe Quality Food), ISO 22000, or BRCGS (British Retail Consortium Global Standards). Also, request copies of their current certificates. Certified suppliers have invested in thorough food-safety systems. They also get third-party verification. This shows their dedication to food safety that exceeds basic compliance.

Verify migration testing results. Suppliers must show that their materials have passed extraction tests. These tests include water, heptane, and other food simulants. These tests are not optional. They are required by regulations to show chemical safety through real testing.

Verify migration testing results. Suppliers must show that their materials have passed extraction tests. These tests include water, heptane, and other food simulants. These tests are not optional. They are required by regulations to show chemical safety through real testing.

Check Material Safety Data Sheets (MSDS). These documents show the chemical makeup and possible dangers of packaging materials, even though it’s less common for solid plastics. They’re particularly important for understanding what happens if materials burn or decompose.

Demand “fatal four” documentation. The industry often tests for BPA, phthalates, heavy metals (not music), and PFAS. These chemicals pose serious health risks. Contamination can happen during processing or recycling, even if these chemicals were not added on purpose.

Check for food-safe embossing. Examine the packaging and look for the fork-and-knife symbol, which indicates the packaging meets safety standards. As previously mentioned, this is not mandatory in the U.S.

Verify recycled content claims. Recycled plastics are closely examined. Contamination can bring non-food-grade materials into the supply chain. Suppliers should provide no-objection letters from the FDA for recycled content applications.

Annual updates matter. Food-contact certifications aren’t permanent. Formulations change, suppliers switch, and regulations evolve. Request updated documentation yearly to ensure continued compliance.

Red Flags That Should Stop You Cold

Certain supplier responses should trigger immediate concern about food-safety compliance. Price alone never justifies risking your brand reputation.

Vague answers about food-safety testing show a lack of knowledge or an attempt to avoid the issue. Food-contact regulations are specific and well-established — there’s no ambiguity about what’s required.

Inability to provide prompt documentation indicates potential compliance gaps. Legitimate food-grade suppliers maintain comprehensive documentation because their customers routinely request it.

Offshore suppliers claiming FDA approval without proper documentation present particular risks. Real FDA approval requires specific testing and documentation that should be readily available.

Generic claims about “food-safe” materials without supporting evidence mean nothing from a regulatory standpoint. Food safety requires specific testing and documentation, not general assertions.

When prices are significantly lower than those of competitors, it often means compromises in materials, testing, or quality control. Food-grade materials and proper testing cost money — prices too good to be true often are just that.

Better Safe Than Sorry

Food-contact packaging safety isn’t about appearances — it’s about confirming that suppliers meet the right standards. The companies that get this right don’t gamble on supplier claims or assume compliance based on looks.

Food-contact packaging safety isn’t about appearances — it’s about confirming that suppliers meet the right standards. The companies that get this right don’t gamble on supplier claims or assume compliance based on looks.

They check documents, know the rules, and build ties with suppliers who see food safety as a top priority. They know that good food-contact materials are like an insurance policy. Without them, a big failure could ruin everything they’ve created.

In an industry where reputation spreads quickly, choosing food-safe packaging is a must. It’s essential for sustainable business success and helps you sleep better at night — something we all could use.

Interested in learning more about plastic food packaging? Visit our Learning Center today and explore a wide range of topics.