Listen to the audio recording of this blog post or check out the featured Podcast about this topic.

At a Glance

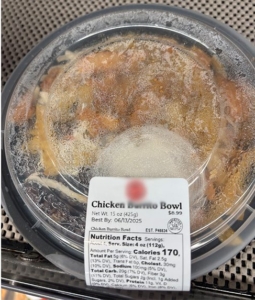

- Condensation in food packaging makes fresh food look soggy and unappetizing, leading to lost sales and frustrated customers.

- It forms when warm food is sealed in cool containers — moisture builds up and drips onto the product, damaging appearance and quality.

- Condensation drives up waste, damages brand perception, and can trigger food safety concerns.

- Three simple strategies solve the issue: cool food before packaging, use ventilated package designs, and maintain temperature consistency throughout your supply chain.

You’ve perfected your signature sandwich for your food business. It’s ideal in every way, from the meat-to-cheese ratio to the clever name you’ve given it (something like “The Breadwinner”). You have invested in premium ingredients and chosen packaging that you thought would display your creation beautifully. But when customers pick up your product from the refrigerated case, they see foggy containers and soggy food that looks anything but appetizing. Condensation in food packaging is more than a visual issue. It can hurt your sales, damage your brand, and frustrate customers. They want fresh and appealing products.

You’re not alone in this battle. Businesses like sandwich shops, meal kit companies, and major retailers are losing money in the food industry. This happens due to a simple scientific fact: warm, humid air meets a cooler surface and causes water droplets to form. It sounds harmless enough, but the consequences are devastating:

- Customers pass by your products because they look unappetizing.

- Food quality deteriorates as moisture drips onto carefully prepared items.

- Your brand reputation suffers when products appear old or poorly handled.

- Increased waste and returns eat into already thin profit margins.

- Regulatory concerns arise when food safety is compromised.

The frustrating part? You can control your food prep, but condensation can sneak up on you. It often ruins your hard work when you least expect it.

Not Raining on Your Parade (or Your Food)

It’s okay. We get it. At Inline Plastics, we’ve been in the business of providing packaging solutions for fresh food companies for over 55 years. This is an ongoing issue that we’ve seen many companies encounter. Today, we’re here to explain how condensation forms. We’ll discuss controlling it and share tips to prevent this “storm inside the package.” This way, you can focus on what really matters — perfecting that vegetarian sandwich option you’ve been getting so close to mastering (the “Lettuce Turnip the Beet” grinder).

The Real Cost of Ignoring This Problem

What makes condensation particularly insidious is how it amplifies other problems. When food touches the lid of its container, condensation doesn’t just form — it creates a direct pathway for moisture to soak into the product. Every bump and jostle during transport spills water droplets onto your carefully crafted food.

What makes condensation particularly insidious is how it amplifies other problems. When food touches the lid of its container, condensation doesn’t just form — it creates a direct pathway for moisture to soak into the product. Every bump and jostle during transport spills water droplets onto your carefully crafted food.

The financial impact compounds quickly. A single condensation event can ruin an entire batch of products. Multiply that by many SKUs, delivery routes, and seasonal temperature changes, and you can have big losses that hurt your bottom line.

But most food professionals don’t realize that condensation isn’t inevitable. It’s entirely preventable when you understand its science and implement the right solutions.

The Science Behind the Solution

Condensation occurs when three conditions align: temperature differential, moisture content, and contact surfaces. The good news is that with the right approach, you can control all three variables.

The critical insight is timing. When warm food is placed directly into packaging and refrigerated, you create the perfect storm for condensation. The warm, humid air inside the package meets the cooling container walls, and physics takes over. However, this process can be avoided entirely with proper temperature management. Check out our tips on how to deal with condensation and fog in warm and hot food applications.

The most effective prevention strategy is surprisingly simple: cool your food before packaging. If food gets to the same temperature as its storage space before sealing, it helps prevent condensation.

Your Action Plan: Three Proven Strategies

You don’t need a PhD in thermodynamics or a million-dollar budget to solve this problem. The following three strategies are so straightforward that you’ll wonder why you didn’t think of them sooner. Think of them as your toolkit for fighting condensation. Each tool solves a part of the problem. Together, they’ll turn your soggy nightmare into a crisp success story.

You don’t need a PhD in thermodynamics or a million-dollar budget to solve this problem. The following three strategies are so straightforward that you’ll wonder why you didn’t think of them sooner. Think of them as your toolkit for fighting condensation. Each tool solves a part of the problem. Together, they’ll turn your soggy nightmare into a crisp success story.

Strategy 1: Master Temperature Control

To prevent condensation, follow the golden rule: keep the air inside the package at the same temperature as outside air. Cool your food products to match their storage temperature before packaging. Cool products are meant to be refrigerated and displayed at the right temperature during production. Don’t wait until after packaging.

Strategy 2: Leverage Smart Package Design

Effective moisture management starts with proper ventilation. Micro-perforations and thoughtfully placed vents enable controlled air exchange, which helps regulate humidity levels inside the package. This balance is essential for maintaining food safety, supporting shelf life, and preserving product quality.

The key is designing packaging that ensures adequate airflow without compromising protection or freshness.

Strategy 3: Environmental Consistency

Maintain consistent temperatures throughout your supply chain. Train your retail locations to store products at appropriate temperatures that match the temperature of the food contents. A cold product in a cold place has little temperature difference, greatly lowering the chance of condensation.

Why This Matters More Than Ever

Today’s consumers have higher expectations than ever before. Social media spreads every negative experience quickly. Customers form first impressions in just seconds as they glance at refrigerated cases. Just one spot of visible condensation can make people think the product is low-quality, outdated, or unsafe. You’ve worked too hard to create (and cleverly name) your signature culinary creations to let them go unseen.

Moreover, sustainability concerns make waste reduction crucial. Every product lost to condensation means wasted food, packaging, energy, and transport resources. Solving condensation goes beyond quick profits. It’s about creating a more sustainable and efficient operation.

Clearing the Air Around Condensation Concerns

The difference between businesses that struggle with condensation and those that have eliminated it comes down to one thing: understanding that condensation is a process, not an inevitability. Control temperature timing, choose the right packaging designs, and keep the environment consistent. This way, your products look great on the shelf, just like when they left your facility.

The difference between businesses that struggle with condensation and those that have eliminated it comes down to one thing: understanding that condensation is a process, not an inevitability. Control temperature timing, choose the right packaging designs, and keep the environment consistent. This way, your products look great on the shelf, just like when they left your facility.

Don’t let condensation continue undermining your hard work and investment. The solutions exist, the science is precise, and the implementation is straightforward. Your customers — and your bottom line — deserve products that look as fresh and appealing as they taste.

Start with your next production run. Cool first, package second, and watch as the condensation problem plaguing your products disappears. Your future self will thank you for taking action today, and your customers will notice the difference immediately.

You have a choice: keep losing sales to a problem you can fix or use these proven strategies. This will boost your product quality and profits significantly.

You’ve got your plan to deal with condensation in plastic packaging for fresh food. Now, it’s time to use your noodle and start thinking about names for that new premium pasta dish.

Do you want to learn more about how to make your products shine with the right packaging? Visit our Learning Center today!