At a Glance

- CPET packaging handles -40°F to 420°F and is perfect for freezer-to-oven meals.

- Made with special thermoforming tools and processing, it keeps its shape and blocks oxygen, water, and grease.

- Recycling is a challenge, but new CPET Light and TPET offer clearer, greener options.

- Use CPET for extreme temps; choose alternatives for moderate heat needs.

First and foremost, dear reader (or listener), please know that we are not making this up.

Your product development team loves the idea of frozen-to-oven meals. But there’s a problem: freezer-safe packaging melts in the oven, while oven-safe options crack in the freezer. This temperature challenge pushes manufacturers and food businesses to make costly compromises. It can also completely stifle product innovation.

But there is one material that may be the answer: CPET. Crystallized polyethylene terephthalate (CPET) — try saying that one fast — solves this problem by handling temperatures from -40°F to 420°F without breaking or warping.

This week, we had the opportunity to speak with Conor Carlin, who serves as Founder and President of Clefs Advisory LLC. Carlin’s distinguished background includes his role as the 2024 President of the Society of Plastics Engineers, as well as his previous position as North American General Manager at ILLIG. He has established himself as an expert in the intersection of packaging and sustainability, bringing comprehensive knowledge across materials science, packaging and recycling technologies, policy development, commercial strategy, and market analysis.

Carlin provides an in-depth exploration of CPET in his recently published report, Thermoformed Packaging Outlook & Analysis. The full report is available for purchase by clicking here.

This article examines how CPET operates. It explains its key role in convenience foods. It also discusses the sustainability challenges that may impact its future.

How CPET Solves the Temperature Problem

CPET works by altering the composition of regular plastic. Think of normal plastic polymers like a messy pile of cooked, tangled spaghetti (we know, the spaghetti you serve isn’t “messy,” it’s “deliciously controlled chaos”). CPET takes that same spaghetti and lines it up in neat rows that stay in place.

Here’s what goes into CPET: about 95% regular plastic, plus 5% special ingredients called nucleating agents. No, these are not affiliated with comic supervillains. These agents are like tiny helpers that organize the plastic molecules into neat patterns.

The magic happens during a special two-step cooking process. First, the plastic gets heated to around 350°F while being shaped into containers. This heat lets the plastic molecules move around and line up properly. Then the containers get cooled down fast to room temperature. This quick cooling freezes those neat molecular rows in place.

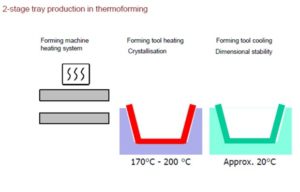

Creating CPET requires specialized machines and tools that operate differently from standard packaging equipment. Normal machines heat plastic once and let it cool slowly during the forming process. CPET machines must warm the sheet more precisely, then move the heated plastic into the forming press where a two-stage mold heats, then rapidly cools (or quenches) the plastic. It’s like having to pause in the middle of making every container to lock in the special structure.

This extra step makes CPET containers take a little longer to produce. Regular PET (polyethylene terephthalate) is produced much more quickly. PET is a common, lightweight plastic used for food packaging. CPET is roughly 15% more expensive than standard materials like PET. This is due to a combination of additives in the resin and the need for specialized tooling. However, this investment creates containers that can be transferred directly from your freezer to a 400°F oven without melting or cracking.

Why Food Companies Choose CPET

CPET became the go-to solution for premium convenience foods because it eliminates the temperature packaging compromise. Food manufacturers can now create products that people can store in the freezer for months. They can cook them right in the original container; no need to switch to oven-safe dishes. (Did someone say “frozen family-size mac n’ cheese?” Yes, please!)

This capability opened entirely new product categories:

- Frozen meals that finish cooking in conventional ovens.

- Meal kits that require high-temperature preparation.

- Restaurant-quality entrees that deliver consistent results regardless of heating method.

- Premium frozen foods that maintain professional presentation from freezer to table.

CPET offers strong barriers against oxygen, water, and grease. It also keeps its shape well. When a frozen dinner comes out of the oven looking just like the package photo, that’s CPET keeping its promise of temperature resistance.

For food manufacturers, this means more market opportunities and simpler packaging. One container stores, heats, and serves food. This design reduces costs and simplifies the process for consumers compared to using multiple layers.

Isn’t Black Plastic a Problem?

Despite its superpowers, CPET has one significant weakness: it’s almost always black, and black plastic is recycling kryptonite. This isn’t just a concern for environmentalists anymore — it’s becoming a real business problem as environmental regulations become stricter and customers increasingly care about sustainability.

The color black comes from two places. First, those special helper ingredients that make CPET work also include pigment, historically carbon black. Food companies often choose black packaging. It gives a premium feel and conceals food that doesn’t look appealing in clear containers.

The problem is that the black pigment is invisible to many of the machines that sort recyclable materials. These machines use special scanners to identify different types of plastic, but many can’t “see” carbon black. Some newer Material Recovery Facilities (MRFs) use advanced scanning technology. This technology can detect black plastics when newer colorants that combine specialty dyes and pigments are used. The challenge is that each MRF has different capabilities — what gets recycled in one city might end up in the landfill in another. Furthermore, not all brands or packaging converters have switched to these new pigments.

Some manufacturers have changed to different dark dyes that look black to us (think of a super-dark blue), but show up on more scanners. But that only fixes part of the problem. Even when black CPET can be sorted properly, there’s not much demand for black recycled plastic.

This puts food manufacturers in a tough spot. CPET helps create products that customers love. But it also raises doubts about whether the packaging will be recycled, even in areas with equipped facilities.

New Solutions on the Horizon

The great news is that researchers and innovators are developing solutions. They aim to maintain CPET’s benefits while also solving recycling challenges and cost concerns.

The coolest new development is called TPET (Therma-PET). TPET toughens plastic by stretching it like taffy. It then molds this plastic into containers, skipping the use of two-stage or heated molds and special chemicals. This offers the same temperature resistance but maintains the plastic’s clarity. That way, it can be recycled with standard bottles and containers. TPET is still under development, so the exact costs are not yet known.

There’s also something called CPET Light. No, it’s not a new beer, but it’s like CPET’s little brother. It can handle temperatures up to 212°F. That’s hot enough for microwaves and soup, like polypropylene packaging. Additionally, it eliminates the complicated two-step forming process. CPET Light is less expensive than full CPET due to its simpler manufacturing process. However, it still costs more than basic plastic packaging. Tests show these containers can survive 30 minutes in a 212°F oven and handle hot liquids at 200°F without warping or cracking.

The best part? CPET Light can be made completely transparent, so it seamlessly integrates into existing recycling systems. It’s grease-resistant and keeps food barriers strong. This makes it great for dairy products, soups, and hot drinks.

Meanwhile, the machines that produce CPET are also improving. Instead of using hot oil to heat the tool (which was messy and dangerous), new machines use electric heaters that are safer, cleaner, and more precise. These improvements are enabling manufacturers to produce CPET containers more efficiently.

Making the Right Choice for Your Business

CPET holds a unique place in food packaging. It’s essential for some applications, yet it has sustainability limits. For products requiring true temperature extremes, few alternatives match its performance. Premium frozen meals, oven-ready foods, and dual-temperature uses depend on CPET’s special qualities.

CPET holds a unique place in food packaging. It’s essential for some applications, yet it has sustainability limits. For products requiring true temperature extremes, few alternatives match its performance. Premium frozen meals, oven-ready foods, and dual-temperature uses depend on CPET’s special qualities.

However, the sustainability landscape is changing rapidly. Environmental regulations are tightening, corporate sustainability commitments are intensifying, and consumer awareness of packaging waste is growing.

The key is matching packaging choice to actual product requirements. Products that truly need freezer-to-oven capability may justify CPET’s sustainability trade-offs. Applications requiring moderate temperatures could use CPET Light or other materials. These alternatives provide better options for end-of-life disposal.

Success means keeping up with new choices, such as TPET. It also involves collaborating with suppliers to find better, sustainable CPET options. Some manufacturers are switching to scanner-detectable pigments. In the world of sustainability, every step counts.

CPET Moving Forward

Here’s the reality check: CPET isn’t perfect, but it’s not going away either.

First things first — figure out what you actually need. Does your product really have to go from the freezer straight into a hot oven? If so, CPET is still your best option, despite its recycling issues. But if you need something that won’t melt when someone heats soup, CPET Light (or polypropylene) could save you money and make you feel better about the environment.

Discuss with your suppliers what’s next. TPET sounds interesting, but it’s still relatively new. The effectiveness and cost have yet to be fully determined.

Keep an eye on the rules in your area. Environmental laws continue to become stricter, and what’s considered acceptable today may become problematic tomorrow. Additionally, customers are becoming more discerning about packaging that can’t be recycled.

Here’s the bottom line: Whoever figures out how to create packaging that can handle extreme temperatures and doesn’t harm the planet will make a fortune. CPET solved the temperature problem (without costing too much), but now someone needs to solve the Earth-friendly problem too, because what good is family-size mac n’ cheese if we don’t have a future in which to enjoy it?

Are you interested in learning more about sustainability and food packaging? Visit our Learning Center today! If you have any questions, don’t hesitate to reach out! We’re here to help!

Would you like to know more about Conor Carlin and his work at Clefs Advisory LLC? Connect with him on LinkedIn today.