At a Glance

- Packaging design isn’t just about looks — it drives performance from production to purchase.

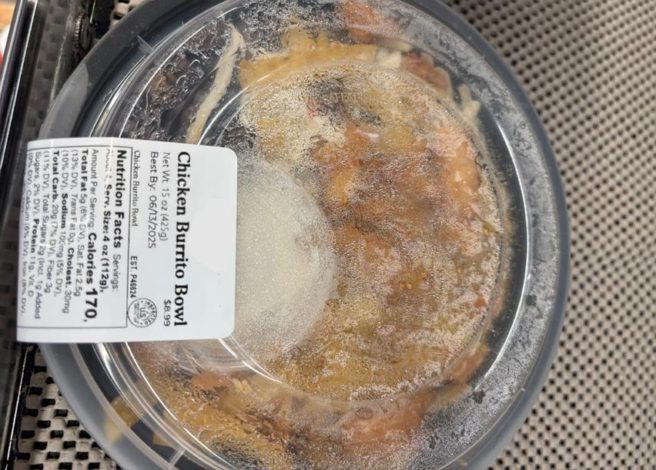

- Flawed design causes stacking issues, seal leaks, and spoilage that hurt profits and trust.

- Watch for seven warning signs: Weak structure, poor seals, bad visibility, outdated design, automation jams, transport damage, and low sustainability.

- Fixing design flaws with the right partner turns packaging into a competitive advantage.

The consumers you’re trying to reach are walking past your product without a second thought. Containers are arriving damaged before they even make it to the shelf. Those beautiful berries lose their vibrant color long before shoppers see them. Sound familiar? Your packaging design might be sabotaging your success without you even realizing it.

After more than 55 years in food packaging, we’ve seen every type of failure. We’ve also learned what really works. Design pitfalls pop up everywhere, from small startups to big food companies. It’s as predictable as a bad sitcom rerun. These failures cost businesses millions in lost sales, wasted products, and damaged reputations.

Food packaging isn’t just about looking pretty on the shelf (though that matters too). It’s the silent salesperson that either makes or breaks your product’s journey from production to purchase. When packaging design fails, it doesn’t just hurt your bottom line; it can destroy consumer trust and brand reputation quickly.

The good news? Most packaging disasters are entirely preventable once you know what to look for. This article covers seven key warning signs that your packaging design may be hurting your business. We’ll explain why these issues happen and show you how to turn your packaging into a competitive edge, because the last thing your delicious food deserves is to be trapped in a container that’s working against it.

The Hidden Costs of Poor Packaging Design

Every day, food businesses lose thousands of dollars to packaging failures that could have been prevented. These aren’t just manufacturing defects — they’re design flaws that cause significant problems in your supply chain, like a costly game of dominoes.

Every day, food businesses lose thousands of dollars to packaging failures that could have been prevented. These aren’t just manufacturing defects — they’re design flaws that cause significant problems in your supply chain, like a costly game of dominoes.

Think about it: When a container can’t stack properly, your employees spend extra time reorganizing shelves (and muttering under their breath). When seals don’t work, products spoil faster. This creates waste and frustrates shoppers, increasing the likelihood of damaging negative reviews. If your packaging fails to highlight your product, sales can suffer, no matter how good your food tastes. It’s a lose-lose situation all around.

The most insidious part? Many businesses don’t realize their packaging is the culprit until it’s too late. They blame marketing, pricing, or competition. But the real problem is right there on the shelf. It’s literally holding their product back and not doing a good job.

How can you succeed when a manufacturer says their packaging shines like Michael Jordan, but it really acts like a rookie?

The Seven Warning Signs Your Packaging is Failing You

Without further ado, let’s get right to it. Here are warning signs that your packaging may be silently plotting against your business.

Warning Sign #1: When Containers Become Unreliable

If your containers won’t stack well, you’re looking at a design emergency. This isn’t just about storage convenience; it’s about structural integrity. But it’s not just about stackability — be on the lookout for the dreaded “BWW-indicators”. Bulging, wobbling, or warped containers show serious design flaws. These issues impact every part of your product’s performance. Bulging and warping occur when gases from your product, like Brussels sprouts or other high-outgassing foods, gather inside a seal that’s too tight. The container literally inflates like a balloon, making it impossible to stack and creates an unstable base. This not only wastes valuable retail space but also makes your product look defective to buyers.

If your containers won’t stack well, you’re looking at a design emergency. This isn’t just about storage convenience; it’s about structural integrity. But it’s not just about stackability — be on the lookout for the dreaded “BWW-indicators”. Bulging, wobbling, or warped containers show serious design flaws. These issues impact every part of your product’s performance. Bulging and warping occur when gases from your product, like Brussels sprouts or other high-outgassing foods, gather inside a seal that’s too tight. The container literally inflates like a balloon, making it impossible to stack and creates an unstable base. This not only wastes valuable retail space but also makes your product look defective to buyers.

Warning Sign #2: Seal Failures Cost More Than Money

Your seal is the guardian of your product’s shelf life. When seals fail, they don’t just let air in — they let freshness out. Certain foods require tighter seals for freshness, while others need venting to release natural gases. For example, chopped onions or broccoli may need outgassing vents to prevent pressure buildup, while baked goods or stable items do better with a simple, consistent seal.

A good seal should be almost invisible to the consumer. It should also provide top-notch protection. If buyers struggle to open your packages or if products spoil fast, your seal design needs immediate attention.

Warning Sign #3: The Merchandising Mishap

Great packaging design should enhance your product, not hide it. The goal is to make the container so transparent to the experience that shoppers focus entirely on your delicious food. However, there’s a fine line between invisible functionality and a forgettable presence.

Your packaging needs to showcase your product effectively while maintaining its protective function. If shoppers can’t see your product well, you lose sales. Also, if the packaging doesn’t enhance your food’s visual appeal, you miss out on essential opportunities to sell.

Is your food hiding behind paper packaging that’s preventing purchasers from seeing your creations? It’s time to look at how this affects your bottom line.

Warning Sign #4: Seasonal and Market Demands

Markets change, seasons shift, and buyer preferences evolve. Packaging that worked perfectly six months ago might be entirely wrong for today’s market. Holiday packaging, seasonal colors, and trending shapes all play roles in merchandising success.

Smart food businesses pick designs that appeal to the mass market. They also keep flexibility for specific uses. This means going beyond just “holding food.” You should think about how your packaging works in various stores, during different seasons, and what shoppers expect. In plain English: Choose packaging that works for lots of different customers and situations, not just one specific use.

Warning Sign #5: The Automation Challenge

Modern food packaging must work seamlessly with automated systems. If your containers jam filling machines or slow down sorting, you’re losing money daily.

Effective packaging design considers the entire journey from production to consumption. This includes manufacturability, automation compatibility, transportation durability, and even recyclability. Each stage presents unique challenges that must be addressed in the initial design phase.

Warning Sign #6: Transportation and Handling Disasters

Your packaging needs to survive the journey from your facility to the consumer’s hands. This means withstanding temperature variations, altitude changes, rough handling, and extended storage periods. Packages that succeed in your facility but fail while being transported reveal design flaws that require urgent attention.

Warning Sign #7: The Sustainability (or Lack Thereof) Factor

Today’s buyers increasingly care about environmental impact. Packaging that is hard to recycle or needs complicated disposal makes purchasing decisions difficult. Single-material designs that work with existing recycling infrastructure provide significant competitive advantages.

The challenge lies in balancing sustainability with functionality. Your packaging needs to protect your product effectively while remaining environmentally responsible. This calls for advanced design thinking and takes into account both current performance and future environmental impact.

Recognition Is the First Step

If you’ve recognized any of these warning signs in your current packaging, don’t panic (Rule Number One). Recognition is the first step toward improvement. Most packaging problems can be solved with thoughtful redesign and proper testing.

If you’ve recognized any of these warning signs in your current packaging, don’t panic (Rule Number One). Recognition is the first step toward improvement. Most packaging problems can be solved with thoughtful redesign and proper testing.

Start by evaluating your current packaging against these criteria:

- Does it stack reliably under normal conditions?

- Are seals appropriate for your specific product type?

- Does it showcase your product effectively?

- Can it handle your entire supply chain journey?

- Is it compatible with modern recycling systems?

Consider a Professional Assessment

Consider having your packaging professionally evaluated. Some obvious problems can have hidden causes. Also, issues you overlook might be costing you a lot of money.

The right packaging design partner will consider more than just the container. They’ll look at your whole business ecosystem, your product features, supply chain needs, retail setting, and consumer wants. This helps them create solutions that work well together.

The right manufacturing partner always cares about how your products perform and how they sell (or don’t).

Success by Design

When packaging design works correctly, it becomes genuinely invisible — but in the best possible way. Purchasers love your fantastic product. Operations run without a hitch, and your brand is linked to quality and dependability. It’s like having a really good wingman; you barely notice they’re there, but somehow everything just works better.

When packaging design works correctly, it becomes genuinely invisible — but in the best possible way. Purchasers love your fantastic product. Operations run without a hitch, and your brand is linked to quality and dependability. It’s like having a really good wingman; you barely notice they’re there, but somehow everything just works better.

Don’t let poor packaging design sabotage your success. Your food deserves containers that enhances rather than hinders its journey to happy shoppers. Investing in good packaging design brings many benefits. It cuts waste, boosts consumer satisfaction, and raises sales. Plus, you can relax knowing your containers are working for you, not against you.

Are you interested in learning more about packaging design and functionality? Visit our Learning Center today and get started on your packaging journey!