At a Glance

- Impact failures with packaging aren’t bad luck — they’re the result of containers that weren’t designed or tested to withstand stacking, drops, and cold storage.

- Impact testing reveals how containers behave at their weakest points, especially corners, across real-world temperatures where plastic becomes more brittle.

- When packaging fails, the true cost goes far beyond lost product, adding labor, safety risks, customer dissatisfaction, and long-term revenue loss.

- Durable packaging is engineered and tested for real conditions, making it effectively invisible to staff and customers because it simply works.

You know that sinking feeling when a consumer’s salad explodes in the parking lot? Or when your produce manager discovers a sticky mess all over the cold case floor? That’s not just bad luck. It’s physics meeting poor packaging, and it’s costing you more than you think.

Every day, food containers travel a journey that would make most of us nervous. They’re stacked, dropped, tossed onto conveyor belts, and sometimes fall from shelves onto unforgiving floors. The question isn’t whether your packaging will face impact — it’s whether it’ll make it through unscathed.

At Inline Plastics, we’ve been in the business of fresh food packaging solutions for over 55 years. In that time, we have rigorously tested our packaging and witnessed firsthand what happens without proper validation.

This article breaks down how impact testing works, why it matters to your bottom line, and what separates containers that hold up from those that don’t.

What Actually Happens During Impact Testing?

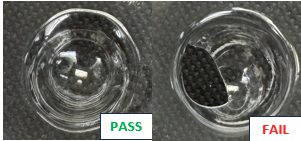

The technical term is “impact testing,” and it’s surprisingly straightforward. A heavy cylindrical weight drops onto packaging from various heights. Start low, observe what happens, then raise the height and repeat.

At lower heights, quality packaging might show a small dent or imprint. That’s a pass — the material absorbed the energy and kept its integrity. But as heights increase, weaker packaging eventually cracks, breaks, or splits. That’s the failure point.

Let’s put our physics hats on for a moment: Impact tests are conducted at different temperatures. Room temperature provides baseline performance. Refrigerated testing mimics cold-case conditions, while freezer testing shows how materials behave at their most brittle — since cold typically makes packaging more prone to cracking or fracture.

The measurement is inch-pounds, which represents impact energy. The physics are: Impact Energy (in-lb) = Weight (lb) × Drop Height (in). Increasing the weight and/or the drop height increases the energy the packaging must absorb without failing.

Why Does Food Packaging Keep Breaking?

Did you know that the container holding your premium crab legs or artisan salad may have never been tested with actual food inside?

Did you know that the container holding your premium crab legs or artisan salad may have never been tested with actual food inside?

A large portion of impact testing happens on empty packages because testing every possible combination of food types, weights, and drop angles would be impossible. Brussels sprouts behave differently from pasta salad, and a container might land at any angle imaginable. So manufacturers test the materials and package design themselves, looking for weak points before products hit the market.

The problem? Not all manufacturers test equally. Some skip rigorous testing altogether, gambling that their packaging will hold up. When it doesn’t, you’re the one dealing with the consequences.

Where Does Packaging Fail First?

The corners of any container are its weakest points. When manufacturers form packaging, the material gets stretched and pulled to create edges where the sides meet. This makes corners thinner than the rest of the container — sometimes significantly thinner.

The base corners carry triple risk. You’ve got two sidewalls meeting at the bottom panel, all joined at one point. That’s three pieces of material coming together at the thinnest, most stressed part of the entire package. Drop a heavy container of guacamole onto its corner, and you’ll understand why testing engineers focus here.

How Much Is Packaging Failure Really Costing You?

Let’s talk numbers, because this isn’t just about messy floors.

Let’s talk numbers, because this isn’t just about messy floors.

Start with the obvious: Lost product. That $8 container of prepared food that pops open during transport? Gone. But someone needs to clean up the mess — there’s your labor cost. If it happened in front of customers, you might need to comp another order. That’s two containers lost plus labor.

Now multiply that across a week, a month, or a quarter. Add the cost of a customer who never comes back but never tells you why. They just disappear, and so does their lifetime value.

Then there’s liability. Leaking containers create slip hazards. Medical bills, potential lawsuits, insurance claims — weak packaging opens the doors of Pandora’s Box, and you definitely want to keep them closed.

What Makes a Container Actually Durable?

Quality packaging isn’t about luck — it’s about engineering. The best containers balance material strength with smart design. They reinforce vulnerable areas. They use material blends tested across a range of temperatures. They’re designed knowing that real-world handling is rough.

Look for containers that survive testing across the full temperature spectrum. A container that performs well at room temperature but cracks in freezer or refrigerated applications forces you to source a second container — and manage separate inventory, SKUs, and reordering processes — driving unnecessary complexity and cost. Similarly, packaging that barely passes testing at minimal drop heights won’t hold up to a three-foot shelf drop or the aggressive handling of a busy lunch rush.

Flimsy packaging feels wrong in your hands — and your customers notice. When staff aren’t confident the container will reach a customer’s car intact, that uncertainty shows. Quality packaging communicates care and professionalism before anyone even opens it.

How Do You Know If Your Packaging Passes the Test?

You probably can’t tour a testing lab, but you can test packaging yourself in ways that matter.

You probably can’t tour a testing lab, but you can test packaging yourself in ways that matter.

Before committing to containers, you should test them in your real-world application. Stack the containers as you would in storage. Do corners dent or crack? Fill containers with your actual products — especially heavy items like proteins or grain salads. Close them. Gently drop one from waist height onto a hard surface. Does the lid pop? Does anything crack?

Try it cold. Put filled containers in your walk-in for a few hours, then repeat the impact test. Cold makes plastic brittle, and if your packaging can’t handle it, it’s better to find out before a customer does.

Watch your returns and complaints. Patterns matter. If you’re consistently dealing with leaking containers or packaging that fails during transport, your current solution isn’t working — no matter how attractive the price point seemed.

The Real Cost of “Good Enough”

Here’s where food business professionals make their biggest mistake: Thinking all packaging is basically the same.

It’s not.

The container that costs $0.10 or $0.15 less per unit but fails one out of every fifty times isn’t saving you money. It’s costing you product, labor, customer trust, and sleep at night. Meanwhile, packaging engineered to handle real-world conditions becomes invisible — in the best way. Staff don’t think about it. Customers don’t complain about it. It just works.

Quality packaging undergoes impact testing at multiple temperatures and heights. It’s designed with vulnerable areas in mind. It’s made from material blends proven to absorb impact without failing. That testing happens before the packaging reaches you, which means you’re not the one discovering its limits through expensive real-world failures.

Sampling Your Options

The next time you evaluate packaging options, ask different questions. Don’t just inquire about price per unit. Ask about testing standards, failure rates, and what happens when packages experience impact.

Better yet, test samples yourself with your actual products under your actual conditions. Because the perfect container on paper means nothing if it can’t survive your refrigerated delivery truck or your stock clerk’s slightly too enthusiastic shelf stocking.

Your packaging should be the least interesting part of your customer’s experience. Not because it’s boring, but because it works so reliably, they never think about it. They think about your delicious food, your convenient service, and how they’ll definitely be back next week.

That’s the difference between packaging that contains food and packaging that protects your investment, your reputation, and your customer relationships. And now you know the kind of testing that separates the two.

Do you want to find out more about product testing? Visit our Learning Center today and explore a wide variety of topics.