At a Glance

- Meat packaging impacts freshness, safety, and visual appeal, using film sealing, vacuum, and modified atmosphere methods to protect quality.

- Different meats need different solutions — like high-OTR films for fresh fish and controlled gas blends for red meat.

- Lighting affects both appearance and shelf life, so retailers balance visibility with color preservation.

- Consumer psychology matters — clear films, labels, and ease of use drive trust and buying decisions.

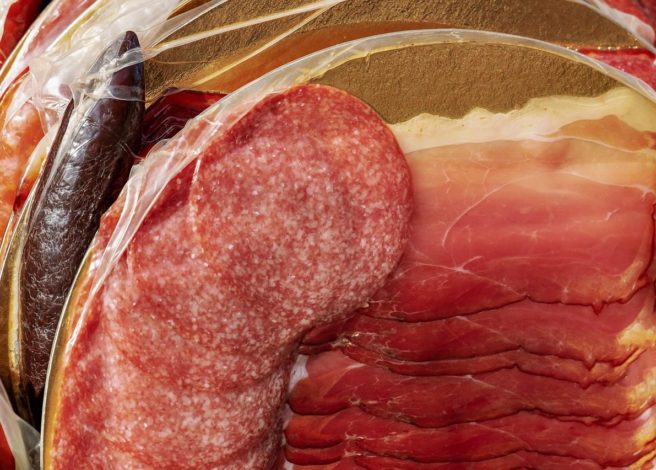

That vibrant, perfectly marbled ribeye catching shoppers’ eyes isn’t just about product quality — it’s strategic packaging engineering at work. The difference in meat packaging goes beyond aesthetics. It represents a sophisticated balance of technology and food science.

Modern meat packaging blends innovation, chemistry, and consumer psychology. Yes, you read that correctly. Understanding advanced meat packaging methods helps food industry professionals make smart choices about product display, safety, and shelf life. This can keep customers returning, especially during BBQ season!

For over 50 years, Inline Plastics has been involved in fresh food packaging and has learned how packaging affects quality, shelf life, and consumer appeal. Drawing on conversations with meat packaging experts across the industry, we’re taking you behind the scenes of what really keeps that steak looking perfect on the shelf. We’ll break down how film sealing technology works, see how it stacks up against traditional containers, and show you the clever lighting tricks that make products pop in the display case. By the end, you’ll understand exactly how packaging choices affect what matters most: quality, freshness, and what catches the attention of your customers. Now, let’s get to the meat of the matter.

Understanding Different Packaging Approaches

Film sealing represents one approach in the spectrum of meat packaging methods. Clamshells usually have one or two layers of rigid PET (polyethylene terephthalate). In contrast, film-sealed packaging uses multi-layer films designed for food preservation. It’s like a custom outfit for each piece of meat.

Film sealing represents one approach in the spectrum of meat packaging methods. Clamshells usually have one or two layers of rigid PET (polyethylene terephthalate). In contrast, film-sealed packaging uses multi-layer films designed for food preservation. It’s like a custom outfit for each piece of meat.

The key difference lies in the composition of these packaging materials. A film-sealed package can have two to fifteen layers, each with its own purpose. The outer layer provides structure. The middle layers provide barrier properties. The innermost layer, usually polyethylene or similar materials, forms a tight seal. This seal blocks air and germs when heat and pressure are used.

The Air We Don’t Breathe: Atmosphere Control in Meat Packaging

One of the most significant advantages of film sealing is atmosphere control within the package. Depending on the product, processors can choose from several approaches:

- Vacuum packaging: This method eliminates all oxygen from the package. It slows down oxidation and helps keep products fresh longer. That’s why vacuum-sealed beef retains quality much longer than store-wrapped cuts.

- Modified atmosphere packaging (MAP): MAP doesn’t just remove air — it replaces it with a specific gas mixture. For red meat, a typical mix is carbon dioxide and nitrogen. Sometimes, there are small amounts of carbon monoxide to keep the nice red color that people want.

- Oxygen-permeable packaging: Some products, like fresh chicken, benefit from controlled oxygen exchange. These packages often incorporate micro perforations that allow odors to escape while maintaining moisture.

The Fish Factor: Why Different Products Need Different Films

Meat packaging isn’t one-size-fits-all. Consider seafood, which presents unique challenges.

Meat packaging isn’t one-size-fits-all. Consider seafood, which presents unique challenges.

Fresh fish requires packaging with a minimum oxygen transmission rate (OTR) of 10,000—a regulatory requirement from the FDA. Why? Because seafood spoilage can occur in ways our senses can’t detect. The packaging controls oxygen flow. This way, when seafood spoils, it changes in smell and appearance. So, consumers can notice these signs and avoid eating spoiled fish (and breathe a heavy sigh of relief!)

This contrasts with frozen seafood, which can use the same high-barrier films used for other meats. Freezing helps preserve items by removing the need for oxygen flow.

The Light Factor: How Display Cases Affect Meat Quality

You obviously want to put your meat in the spotlight, but be careful when doing so. Beyond the package, retail lighting plays a crucial role in meat presentation and preservation. Store lighting presents a fascinating balancing act:

- Retailers want bright lights to showcase products and attract customers

- But intense light accelerates discoloration and shortens shelf life

Meat departments manage their display cases carefully. They use first-in-first-out systems and keep products under direct light to a minimum. Ground beef usually takes up more display space than steaks because it sells faster and spends less time under the lights.

Different meats respond differently to light exposure. Processed meats, such as bologna, are sensitive because of their altered proteins and fat content. Meanwhile, fresh red meat can quickly lose its appealing color under harsh lighting.

The industry created specialized lighting systems. These systems use LED and fluorescent lights to highlight meat’s best color. They also help minimize degradation. This shows another layer of science in the meat case. It teams up with packaging to enhance appeal and improve shelf life.

Consumer Psychology and Packaging Design

The visual appeal of meat packaging significantly influences purchasing decisions. Consumers often judge product quality based on packaging before considering price or brand.

The visual appeal of meat packaging significantly influences purchasing decisions. Consumers often judge product quality based on packaging before considering price or brand.

For meat products, several psychological factors come into play:

- Color visibility: Packages that show the meat’s natural color seem fresher, which is why clear films are so popular.

- Perceived freshness: Different packaging styles evoke different perceptions. Vacuum-sealed products show longer shelf life and preservation. Butcher paper suggests skill and craftsmanship.

- Handling experience: How packaging feels, opens, and stores impacts consumer satisfaction. Rigid containers provide stability, while film packages minimize perceived waste.

- Trust signals: Clear labels and a smart look boost consumer confidence in product safety and quality.

The best meat packaging combines technical performance with key psychological factors.

Sustainability Challenges

Despite advances in packaging technology, recyclability remains a significant challenge. Most meat packaging fails recyclability standards for several reasons:

- Food contamination makes many otherwise recyclable materials non-recyclable

- Multi-layer films require chemical separation that only a few U.S. facilities can perform

Why This Matters to Food Industry Professionals

Knowing how packaging works is key in the food industry. It impacts everything, from product development to retail strategy.

- Manufacturers need to select the right film properties for each specific product

- Retailers must balance display lighting with shelf-life considerations

- Butchers and meat processors need equipment that seals packages well and controls the atmosphere.

- Product developers should consider packaging implications from the outset of the design process.

In a competitive market, how products look and their freshness influence buying choices. The science of packaging can catch a consumer’s attention. After all, many people “buy with their eyes.”

Meat Packaging: A Rare Medium Well Done

Meat packaging blends art and science. It is key in food safety, consumer psychology, and retail strategy. The field continues to evolve, with new materials, sealing technologies, and lighting systems emerging regularly. Successful packaging solutions must balance product protection, visual appeal, and shelf life requirements.

Food industry pros can boost product quality and shelf life by understanding the needs of various meat products. Staying updated on innovations also helps enhance the consumer experience. In today’s competitive marketplace, thoughtful packaging decisions create value throughout the supply chain — from processor to retailer to the consumer’s kitchen (or grill!).

Are you interested in learning more about packaging solutions? Visit our Learning Center today. If you have any questions, don’t hesitate to contact us. We’re here to help!