At a Glance

- Ribbed walls = strength with less plastic, offering structural support and sustainability through material reduction.

- Smooth walls = premium look and clarity, boosting product visibility and shelf appeal.

- Switching to smooth may increase cost or thickness unless design is optimized for balance.

- Best choice depends on product and positioning: ribbed for value/bulk items, smooth for boutique/prepared foods.

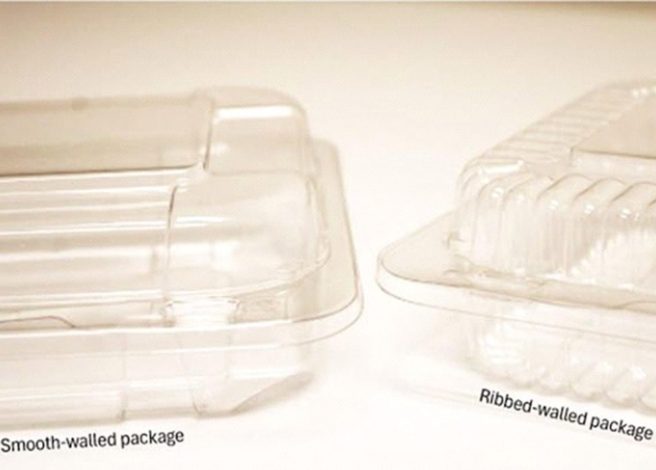

Ever grabbed a container of cookies and noticed those distinctive raised lines running along its sides? Or picked up a premium dessert in a sleek, crystal-clear, smooth package? That subtle difference represents a crucial strategic decision in the food packaging world. Beneath those grooves and sleek surfaces, a fascinating battle unfolds. It’s a clash of tradition versus innovation, structure paired with aesthetics, and cost weighed against presentation. If you’re a food brand manager, packaging buyer, or retailer, you’ve probably had to choose between ribbed-walled and smooth-walled containers. It’s not just about how they look. It’s about protecting your product, delighting your customers, and optimizing your bottom line.

The ribs on your packaging do more than add visual appeal — they protect the product, enhance stacking strength, and support sustainability initiatives by reducing material use. But too often, packaging designs force you to choose: style or strength? A premium look or light materials?

At Inline Plastics, we know how stressful it is to juggle performance, cost, and consumer expectations. With 55 years of experience, we’ve guided hundreds of brands and helped them choose between ribbed-walled and smooth-walled packaging. Our goal is to create containers that benefit their products and their customers.

Packaging design reveals how small details can greatly affect both manufacturers and consumers. It’s time to compare these approaches and see if there is a clear winner.

What Are Ribbed-Walls in Food Packaging?

“Ribbed” walls refers to the raised grooves or textured patterns on the sides of many food containers. These design features began as structural elements and are now closely tied to traditional food packaging. Ribbed-walls aren’t merely decorative — they are crucial in maintaining container integrity.

“Ribbed” walls refers to the raised grooves or textured patterns on the sides of many food containers. These design features began as structural elements and are now closely tied to traditional food packaging. Ribbed-walls aren’t merely decorative — they are crucial in maintaining container integrity.

The primary function of ribbed-walls is to provide strength and rigidity to containers. Manufacturers can place ribs around the packaging’s walls and corners, allowing them to use “lighter gauge” (thinner) plastic while maintaining enough strength. This design prevents containers from bending, collapsing, or changing shape when stacked or filled with food.

These ribs usually run along the edges of packages. This leaves the top clear, like a “window,” so consumers can see the contents inside. This classic design keeps things visible while also providing strong support. It ensures the container walls are sturdy enough to protect the product they’re holding.

The Advantages of Ribbed-Walled Packaging

Structural Integrity Without Extra Material

The biggest benefit of ribbed-walls is that they keep strength while using less plastic. This design lets manufacturers use lighter, thinner materials which can still make strong containers while still helping retailers and suppliers cut costs. It’s a budget-friendly choice that doesn’t sacrifice performance. In this instance, “less is more!”

Sustainability Benefits

From a sustainability perspective, ribbed-walls are important in material reduction efforts. This design feature helps reduce plastic use while maintaining strength because the ribs make the container sturdier and better able to handle pressure. Without these structural elements, smooth-walled designs would require thicker plastic to provide the same level of strength and rigidity. As a result, ribbed-walled containers can be a more sustainable choice, since they enable manufacturers to use less material without compromising durability — a key factor when reducing plastic use is a priority.

From a sustainability perspective, ribbed-walls are important in material reduction efforts. This design feature helps reduce plastic use while maintaining strength because the ribs make the container sturdier and better able to handle pressure. Without these structural elements, smooth-walled designs would require thicker plastic to provide the same level of strength and rigidity. As a result, ribbed-walled containers can be a more sustainable choice, since they enable manufacturers to use less material without compromising durability — a key factor when reducing plastic use is a priority.

Proven Reliability

These designs have shown they can reliably protect food products in many cases, particularly in the bakery section of the grocery store perimeter, where ribbed-walled packages are most commonly used to safeguard items like cakes, muffins, and pastries. The old saying, “If it ain’t broke, don’t fix it,” works well here.

What Are the Limitations of Ribbed-Walls?

Impact on Visual Presentation

Despite their functional benefits, ribbed-walls affect the visual presentation of packaged food. The textured surface can hinder a clear view of the contents, potentially diminishing the product’s visual appeal. In today’s market, presentation matters more than ever. Customers often “buy with their eyes,” making this limitation even more important.

Perceived Value and Positioning

Ribbed-walled packaging is often associated with budget-friendly options rather than premium offerings. Consumers link smooth, modern designs to higher quality. In contrast, ribbed-walled containers may suggest a focus on value instead of a premium feel.

The Shift Toward Smooth-Walled Packaging

Retailers are noticing changes in consumer preferences. Many are now asking for less ribbed-walls on packaging or for the ribs to be removed completely. Several factors drive this shift:

Retailers are noticing changes in consumer preferences. Many are now asking for less ribbed-walls on packaging or for the ribs to be removed completely. Several factors drive this shift:

Modern Aesthetic Appeal

Smooth-walled containers project a more contemporary, upscale image. Clean lines and smooth surfaces match modern design trends. They can also help showcase products as premium choices on store shelves.

Enhanced Product Visibility

Reducing the amount of ribbed-walls improves product visibility, allowing consumers to see what they’re purchasing better. Enhanced transparency is crucial for prepared foods and specialty items, which rely heavily on visual appeal to attract buyers.

Differentiation in a Crowded Market

Packaging design becomes an important differentiator as food retailers look for ways to stand out. Switching from ribbed-walled containers to smooth-walled ones can make products stand out on crowded shelves.

The Material and Cost Implications

The transition from ribbed-walled to smooth-walled packaging isn’t always straightforward. When ribbed-walls are reduced or eliminated, manufacturers and retailers often face a critical decision: should they increase the thickness of the material (the gauge) to maintain structural integrity? If they don’t, the container may fail to protect the product — leading to damage, waste, and dissatisfied customers. If they do, it typically means using more plastic, which raises both material costs and impacts sustainability efforts.

However, when a ribbed-walled package is designed properly — without excess material — any marginal increase in cost from switching to a thicker smooth-walled design should ideally be offset by higher sales. That’s because smooth-walled packaging can deliver stronger shelf appeal and premium positioning, helping retailers justify the added expense.

Finding the Right Balance

It’s important to consider your product’s applications to help you decide which design is right for you.

The industry backs both ribbed-walled packaging and smooth-walled options. This is because each application has unique needs.

Applications Where Ribbed-Walls Remain Popular

- Value-oriented product lines

- Applications where structural performance is prioritized over aesthetics

- Traditional bakery and deli items

- High-volume, cost-sensitive retail segments

Applications Trending Toward Smooth-Walls

- Premium prepared foods

- Specialty and gourmet offerings

- Modern retail environments that focus on presentation

- Brand-forward products where packaging is part of the brand experience

Smooth-Walled or Ribbed-Walled? The Great Packaging Debate

Who knew tiny grooves could cause such a stir? Yet the ribbed-walled debate continues across supermarket aisles and processors nationwide.

Who knew tiny grooves could cause such a stir? Yet the ribbed-walled debate continues across supermarket aisles and processors nationwide.

Ribbed-walled containers are the trusty workhorses of the fresh bakery aisle and deli counter. They provide strength, are easy to make, and are better for sustainability. Smooth-walled options grab attention with their sleek surfaces and are more likely to drive higher sales. It’s like trading your dad’s reliable sedan for a flashy sports car with tinted windows.

The good news? This isn’t a winner-takes-all packaging showdown. Smart brands know that sometimes you need the packaging equivalent of sensible shoes, and other times, nothing but stilettos will do.

With the right packaging, your products arrive fresh, look irresistible on shelves, and align with your brand’s values. You gain confidence knowing you’ve made a smart, strategic choice that sets your product apart and delights your customers.

Whether ribbed-walled for extra strength or smooth-walled for extra style, the best packaging safely delivers the product home and excites the consumer to open it.

Ready to find the right packaging for your brand? Speak with our packaging experts today. Want to explore more on your own? Check out our Learning Center for additional insights.