Jun 02, 2025

The Way Nitrogen Affects Food Freshness May Surprise You

Nitrogen flushing extends freshness by replacing oxygen in packages — slowing browning in produce and oxidation in meats and cheeses. Fresh produce gets a head start: reducing oxygen to 5–8% right away helps maintain color and quality. High-barrier packaging and MAP work for proteins: aiming for near-zero oxygen to preserve flavor and safety. Easy to […]

Read More +

May 30, 2025

How Controlling Fruit Purge Can Save Your Fresh-Cut Products Today

Fruit purge control is essential — managing expelled juices prevents soggy packaging, microbial growth, and product damage. Drainage systems (pads, trays, mesh) wick away excess liquid, keeping fruit fresh and appealing. Modified atmosphere packaging (MAP) reduces respiration and purge by adjusting gas levels around the fruit. Temperature control and rapid sealing are key — keeping […]

Read More +

May 28, 2025

The U.S. Plastics Pact: What Food Business Pros Need to Know

Plastic pact initiatives push brands toward PCR and circular systems, driving targets like 30% post-consumer recycled content and eliminating problematic plastics. Participation reduces risk, helping companies avoid future bans and align with retailer and policy expectations. Reports and data from the Pact offer actionable market insights, guiding strategic packaging decisions. Adapting takes time and investment, […]

Read More +

May 26, 2025

Understanding Carbon Footprints: A Must for Food Industry Professionals

Understanding carbon footprints helps optimize packaging, tracking CO₂e from resin to disposal to identify reduction opportunities. Lightweight plastics lower emissions, often outperforming heavier alternatives in overall lifecycle impact. Food waste prevention is vital, as packaging that keeps food fresh significantly cuts embedded carbon. Data-driven decisions pay: using LCA tools and benchmarking leads to smarter, greener […]

Read More +

May 23, 2025

Sealed to Perfection: The Hidden Science of Meat Packaging

Meat packaging impacts freshness, safety, and visual appeal, using film sealing, vacuum, and modified atmosphere methods to protect quality. Different meats need different solutions — like high-OTR films for fresh fish and controlled gas blends for red meat. Lighting affects both appearance and shelf life, so retailers balance visibility with color preservation. Consumer psychology matters […]

Read More +

May 21, 2025

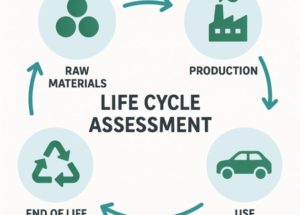

This is Why LCAs Are Reshaping Food Industry Decisions

A life cycle assessment can help businesses reduce environmental impact, tracking effects from raw materials to end-of-life. It reveals trade-offs like material weight vs. emissions, enabling smarter packaging decisions. LCA drives innovation in reuse, recycling, and material sourcing across the supply chain. Sharing LCA results builds trust, aligning brands with sustainability goals and customer expectations. […]

Read More +

May 19, 2025

Aluminum vs. Plastic Packaging: Pros, Cons, and Real-World Considerations

Aluminum and plastic both have unique strengths — aluminum offers high barrier protection and recyclability, while plastics excel in light weight and design flexibility. Plastics typically have a lower carbon footprint during production and transport due to their lighter mass. Aluminum wins on reuse and infinite recyclability, but can require more energy to produce and […]

Read More +

May 16, 2025

Is PEF the Future of Fresh Food Packaging?

PEF food packaging delivers superior barrier properties — it blocks gases and moisture better than PET, extending shelf life. It’s fully bio-based and recyclable, offering a more sustainable alternative to fossil-fuel plastics. Adoption challenges include costs and supply, but pilot projects show real-world promise. PEF fits brand goals for freshness and sustainability, attracting forward-thinking food […]

Read More +

May 14, 2025

What is Modified Atmosphere Packaging & Can It Extend Shelf Life?

Modified atmosphere packaging uses tailored gas mixes (like low O₂, high CO₂) to slow spoilage and protect freshness. It extends shelf life significantly, especially for meats, produce, and fresh-cut foods. Packaging materials and seal integrity are critical to maintain the right gas balance over time. MAP systems require investment, including gas control equipment and ongoing […]

Read More +

May 12, 2025

How Does Film Sealing Stack Up to Rigid Plastic Packaging?

Film sealing offers flexible protection, creating air-tight, tamper-evident pouches that conform to product shape. It’s lightweight and efficient, often using less material than rigid containers and reducing transport costs. Barrier properties vary, so film structure must match product needs (moisture, oxygen, puncture resistance). Rigid packaging wins on rigidity and stackability, but film sealing excels in […]

Read More +