At a Glance

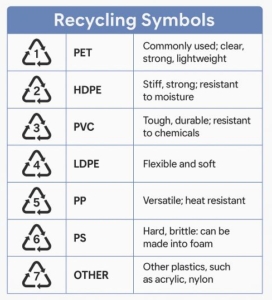

- RIC numbers (1–7) identify plastic types, not recyclability — e.g., “1” means PET, “2” means HDPE, “5” means PP.

- Symbols help sort plastics, so recyclers know what material they’re handling — not an assurance your local program recycles it.

- Consumer confusion is common — many mistake RIC for a recycling promise, leading to sorting mistakes.

- Know your market: Check RIC use to align packaging choices with what recyclers in your region actually accept.

Those codes on packaging may not mean what you think they do. But before we get there, let’s set the scene.

If you work in the food business, you face mounting pressure. Your customers increasingly demand sustainable packaging choices, your competitors are touting their environmentally friendly credentials, and you need to make purchasing decisions that align with both your values and bottom line. But when you flip over packaging and see those triangular recycling symbols with numbers inside, confusion begins, prompting endless questions like:

- What do these symbols actually mean?

- Does “two in a triangle” mean it has been recycled twice?

- If I see the arrows on the packaging, does that always mean it’s recyclable?

- Which packaging choices truly support your sustainability goals?

- How can you confidently communicate these decisions to your environmentally conscious consumers?

- Shouldn’t this all be simpler?

You’re not alone if you’ve ever been confused by these symbols. Many Americans misunderstand what these symbols are communicating.

Let’s clear up the confusion and empower you to be a more informed member of the recycling community!

The Symbolic Confusion

Not understanding these symbols leads to three critical problems:

- Misaligned purchasing decisions: Without understanding what the symbols mean, you might choose packaging that looks sustainable but creates recycling challenges for your customers.

- Customer communication gaps: When customers ask about your packaging choices, vague or incorrect information undermines your credibility and their trust in your brand’s sustainability commitment.

- Competitive disadvantage: Companies that truly understand sustainable packaging can make better decisions and communicate more effectively about their environmental impact.

Before we discuss each symbol, here’s one key fact: these are not “recycling symbols” as most people think.

They’re called resin identification codes (RICs), which identify the type of plastic resin the item is made from. This code does not automatically mean the item is recyclable in your area. This distinction is crucial for making informed purchasing decisions.

How Do You Identify and Utilize the RICs?

Here’s a guide, with insights from the Association of Plastics Recyclers (APR), on what each number means and how it fits into the recycling system:

Tier 1: Your Go-To Sustainable Choices

Tier 1: Your Go-To Sustainable Choices

1 (PET): Polyethylene terephthalate

- Your packaging: Clear containers, bottles, lightweight food packaging.

- Why choose it: Excellent recycling infrastructure, widely accepted by municipal programs.

2 (HDPE): High-density polyethylene

- Your packaging: Opaque containers, milk jugs, and some food storage containers.

- Why choose it: Robust recycling market, solvent and UV resistant.

5 (PP): Polypropylene

- Your packaging: Yogurt containers, bottle caps, and microwave-safe containers.

- Why choose it: Heat and chemical resistant, increasingly recyclable.

Tier 2: Proceed With Caution

4 (LDPE): Low-density polyethylene

- Your packaging: Flexible films, bags, some squeeze bottles.

- Challenge: Requires special collection (store drop-off programs).

- Strategy: Partner with suppliers who participate in film recycling programs.

Tier 3: Avoid When Possible

3 (PVC): Polyvinyl chloride

- Why avoid: Limited recycling infrastructure, health concerns during production.

- Better alternatives: PET or HDPE for similar applications.

6 (PS): Polystyrene (Styrofoam)

- Why avoid: It is not accepted by most recycling programs and is banned in some states, like California, due to environmental concerns.

- Better alternatives: PET containers or molded fiber options.

7 (Other): Mixed or specialty plastics

- Why avoid: Difficult to process, limited recycling options.

- Strategy: Evaluate case-by-case based on specific material composition.

Your Success Strategy: Implementation Steps

Now that you know which resins deserve the sustainability “red light” and which ones get the “green light,” it’s time to put this knowledge to work. Here’s your roadmap from recycling confusion to packaging confidence:

Now that you know which resins deserve the sustainability “red light” and which ones get the “green light,” it’s time to put this knowledge to work. Here’s your roadmap from recycling confusion to packaging confidence:

Step 1: Audit Your Current Packaging

Review your existing packaging suppliers and identify the RIC codes on your primary containers. Calculate what percentage falls into Tier 1 versus problematic categories.

Step 2: Develop Supplier Conversations

Use this knowledge to start informed discussions with packaging suppliers. Ask specific questions about RIC codes and recycling infrastructure in your market areas. Some of these questions may sound like:

- “What percentage of your food packaging offerings falls into RIC codes 1, 2, and 5?”

- “Can you provide documentation on recycling acceptance rates for this packaging in our primary market regions?”

- “What alternative materials do you offer if we want to move away from PVC or polystyrene packaging?”

Step 3: Create Customer Communication Tools

Develop clear, factual language about your packaging choices. Focus on the recycling infrastructure and practical benefits rather than vague sustainability claims.

You can also replace generic environmental buzzwords with specific, actionable information your customers can use:

Step 4: Train Your Team

Ensure your customer-facing staff understand RIC codes so they can answer questions confidently and accurately. Remember: teamwork makes the sustainability dream work.

How Do You Build Trust Through Informed Choices?

You achieve multiple wins when you make packaging decisions based on RIC knowledge. Customer trust builds when your responses to sustainability questions demonstrate an in-depth awareness. Operational efficiency improves as better packaging choices reduce customer complaints and returns. You gain a competitive advantage by supporting your knowledge with facts.

A Symbol for a Better Future

It’s always important to first identify your region’s recycling programs and acceptance rates. You can use helpful tools like How2Recycle (click here) to get specific information.

It’s always important to first identify your region’s recycling programs and acceptance rates. You can use helpful tools like How2Recycle (click here) to get specific information.

Next, when you evaluate packaging options, flip the container over and check the RIC code. Use the info you’ve gathered here to guide your decisions, and remember that small, informed choices compound into significant competitive advantages.

Your customers are watching. Your competitors are learning. And somewhere, there’s a sustainability-savvy customer ready to choose your brand over another simply because you can explain why your packaging makes sense. The question isn’t whether the food industry will become more sophisticated about packaging sustainability — it’s whether you’ll lead the charge or get left explaining why you’re still using outdated materials while everyone else has moved on.

Are you interested in learning more about sustainability? Visit our Learning Center today! If you have any questions, don’t hesitate to reach out. We’re here to help.